Active electronics are essential components that help control electrical signals, but they typically rely on semiconductor devices, which can only be produced in specialized manufacturing centers. This limitation became evident during the Covid-19 pandemic when a shortage of electronics led to increased costs and impacted various sectors of society.

However, researchers at MIT have made significant strides in advancing the field of 3D-printed active electronics. By successfully creating fully 3D-printed resettable fuses without the need for semiconductors, they have opened up possibilities for democratizing electronics fabrication. These semiconductor-free devices, made from standard 3D printing hardware and affordable, biodegradable materials, can perform switching functions similar to semiconductor-based transistors, albeit with lower performance levels.

While the 3D-printed devices may not match the efficiency of silicon transistors, they can still be used for basic control operations, such as regulating the speed of electric motors. The researchers aim to leverage this technology to bring smart hardware capabilities to locations far from traditional manufacturing centers, ultimately making electronics more accessible to a wider audience.

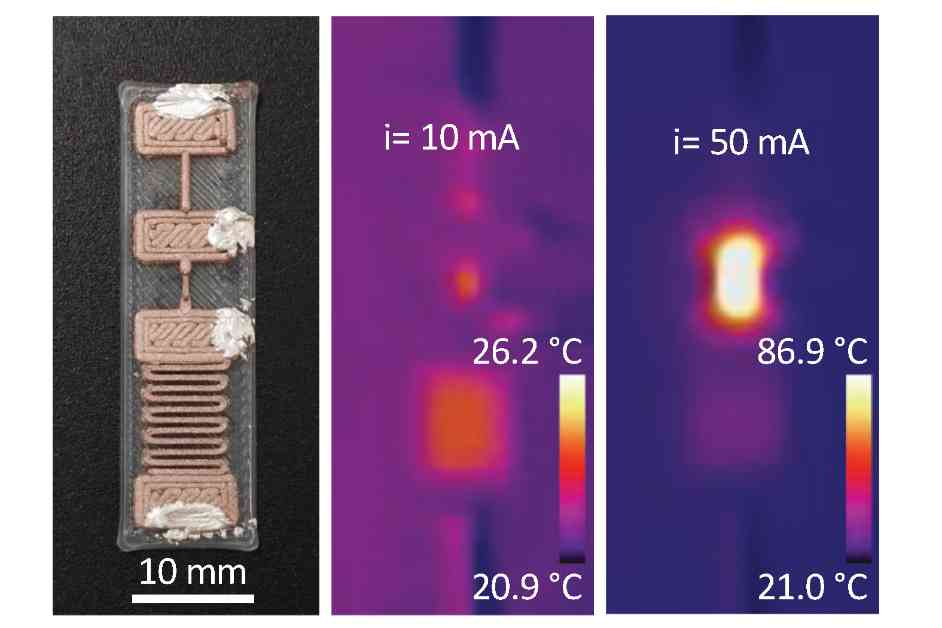

The project originated from an experiment involving the fabrication of magnetic coils using extrusion printing, during which the researchers discovered a unique property in a polymer filament doped with copper nanoparticles. This material exhibited a spike in resistance when subjected to electric current, enabling the creation of transistors that function as switches similar to those made from silicon.

Despite facing challenges in finding alternative printable materials that could replicate this phenomenon, the researchers remain optimistic about the potential of 3D-printed active electronics. By utilizing the polymeric positive temperature coefficient and copper particle dispersion, they have successfully printed switches capable of regulating resistance in semiconductor-free logic gates.

While the current devices may not match the performance of silicon-based transistors, they offer a sustainable and energy-efficient alternative for simpler control and processing tasks. The researchers aim to explore the integration of additional functionalities, such as magnetic microparticles, into the polymer filament to expand the capabilities of 3D-printed electronics further.

Looking ahead, the team envisions a future where fully functional electronics can be printed using extrusion 3D printing technology. By refining the printing process and optimizing circuit designs, they hope to push the boundaries of performance and complexity in 3D-printed active electronics. The potential applications of this technology extend beyond Earth, with possibilities for on-demand 3D printing of mechatronics in spacecraft.

Overall, the MIT team’s breakthrough in 3D-printed active electronics represents a significant step towards revolutionizing the field of electronics fabrication. By combining innovative materials, sustainable practices, and cutting-edge technology, they are paving the way for a more inclusive and accessible future in electronics manufacturing.